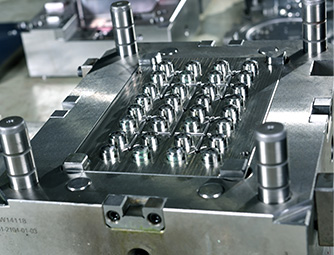

Precision structure parts with critical tolerance;

Outer parts need perfect appearance;

Transparent parts;

Double-material parts (by over mold);

Parts with engineer material such as GF included.

Zinc alloy castings

Aluminum alloy castings

Mg alloy castings

Prototype

Metal stamping, stretching

CNC machining (5X CNC)

Silicone parts

18 years experiences

ISO9001 qualified

TS16949 qualified

Instant quote

Flexible for low/high volume

Strict quality control

Competitive price

From ideas to bringing products to market, Hongqiao is a full-spectrum problems solver to meet your different demands. Full services provided from prototype, mold building to mass production, and surface treatment.

By focusing one quality control, Hongqiao has been a reliable manufacturer, and set up long cooperation with customers.

It is not easy to provide high quality and make it affordable for all-sizes companies, which owes to our lean production, we trust our competitiveness is just customers'.

Customer relationships are our important property, so we provide 365 days 1 to 1 on-call services and support, and the quotes in 24hours.

Inquiry

Quotation & Initial Structure Analysis

Price Approval

Deposit

DFM

Mold Design & Final Part Drawing

Mold Building (Schedule & Weekly Process Report)

Send Initial Sample

STAFF

ENGINEERS

29 Sets of Injection Machines

12 Sets Casting Machines

18+ Years’ Experiences

Profoto makes photography lighting equipment and is within its niche the largest and most renowned company in the world. In other words, the world’s best photographers, fashion photographers in particular, use Profoto lighting. Profoto has a turnover of 700 MSEK, its headquarters in Sweden, subsidiaries in New York, Tokyo, Hamburg, Paris, London and Scandinavia, and distributors in nearly 50 countries. The business scope includes both the technical development and the selling of premium lighting products to the best photographers in the industry. The company was founded in 1968. Today, Profoto combines its heritage of photographic excellence with a young, dynamic and disciplined culture. This combination has during the last ten years turned Profoto into one of the most profitable and respected companies in the business.

Set up new energy shop to meet the demand for automotive customers, it improved the efficiency a lot and cut the cost meanwhile.

Introduced 4 sets of plastic injection machines, both of them are 200 tons, the brand is Hitachi; and 2 sets of Taiwan High Speed CNC machines.

1000mm*800mm*800mm

29 sets of injection machines, from 88T to 850T.

Depends on your requirement, we don’t only have experiences for normal material such as ABS, PC, PPA, POM, but also for engineer material such as PBT, and Glass Fiber material.

12 sets of casting machines, from 88T to 400T, hot chamber and cold chamber.

We know how to avoid holes in the castings, with X-ray zero defect checker for them, skills for high efficiency post-treatment such as drilling holes and tapping which also cut the cost a lot.